Organic solvent nanofiltration

PURAMEM® membranes for OSN applications

Evonik's PURAMEM® stand for innovative membranes for organic solvent nanofiltration. These OSN membranes provide efficient separations at near-ambient temperatures without the need for a phase change of the liquid feed.

DOWNLOAD

The new frontier in molecular separation

Molecular scale separations in aqueous solutions using membranes have been possible since the latter part of the 20th century, with the advent of reverse osmosis and nanofiltration for separation of ions and other molecules. Until recently, industrial applications of both separation techniques have been almost exclusively in the treatment of waste water, desalination, and the food and beverage industry. Membrane separation of molecules dissolved in organic liquids (Organic Solvent Nanofiltration, OSN) has emerged as a new area of membrane science during the last decade, with huge potential for applications across chemical-related industry sectors.

This is reflected in a huge interest. The main reason? Common purification processes – such as distillation, extraction, chromatography, adsorption, and crystallization – can be energy or materials intensive, or suffer from problems of robustness. It is generally accepted that “...separation processes account for between 40-70% of both the capital and operating costs in industry...” . A simple calculation, based on concentrating a dilute solute in a typical solvent by a factor of 10, shows that OSN requires less than 10% of the energy of thermal separation techniques such as distillation. Clearly, OSN can make dramatic cost savings.

Main applications for PURAMEM® membranes

Development in OSN has created various critical applications in molecular separation including:

- Removal of polymeric impurities

- Product purification

- Monomer/dimer separation

- Molecular fractionation

- Room temperature solvent exchange

- Catalyst recovery and recycle

- Color removal

- Solvent recycling

Benefits with Evonik's membranes for organic solvent nanofiltration

- Increased product value

- Reduced operating cost

- Reduced processing time

- Environmentally friendly

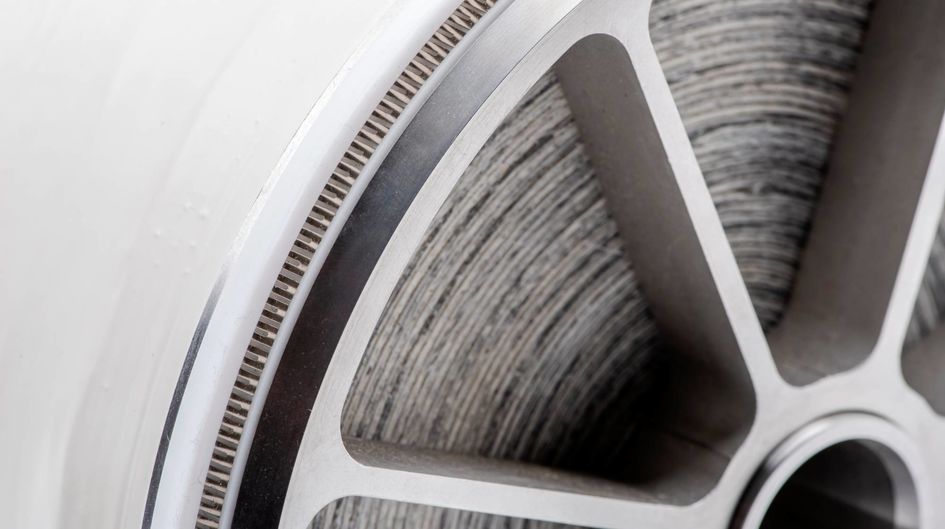

Readily Scalable Technology

We will accompany you throughout process development, from initial proof-of-concept to the proof-of-process. In addition to industrial upscaling to our PURAMEM® poduct family, we also offer customized process development services and can provide customers with lab and pilot scale test equipment.